Dispensing Industry Solution

1. Dispensing Process Overview

Dispensing refers to applying adhesives or curing agents onto products requiring encapsulation or sealing to achieve fixation and sealing effects.

Traditional Dispensing:

Operators manually use glue guns or dispensing needles to control adhesive flow and placement.

Limitations: Only suitable for simple tasks and small-scale production; lacks guaranteed success rates and speed improvements.

Automated Dispensing:

Utilizes automated equipment (e.g., robots) with programming and precision control to achieve high-accuracy, high-efficiency dispensing.

Applications: Large-scale production and complex dispensing requirements.

2. Application Classification & Function Description

Dispensing Applications by Form:

Five-axis linkage precision dispensing

High-speed dispensing machines

Inline/desktop dispensing systems

Robotic arm dispensing

Equipment Functional Classification:

| Category | Function |

|---|---|

| Actuator | Executes dispensing operations |

| Drive Mechanism | Enhances precision and quality of dispensing operations |

| Control System | Manages overall system operations |

3. iNexBot Dispensing Process

![img]() Preview

Preview

iNexBot Dispensing Workstation Overview:

iNexBot provides complete automated dispensing system solutions, specializing in high-quality, stable automatic dispensing equipment for 3C manufacturing and automotive electronics.

Workstation Components:

Vision module

Safety component module

Dispensing valve module

Sensor module

Control Support: PLC/PWM/IO

Precision: Coating trajectory control up to 0.001mm

Features: Auto erasing/Auto needle alignment/Auto calibration

4. Nabote Dispensing Process Steps

Power on

Manual start

Place workpiece

Visual inspection of workpiece position

Begin dispensing

End coating

Visual inspection of coating effect

Process completion

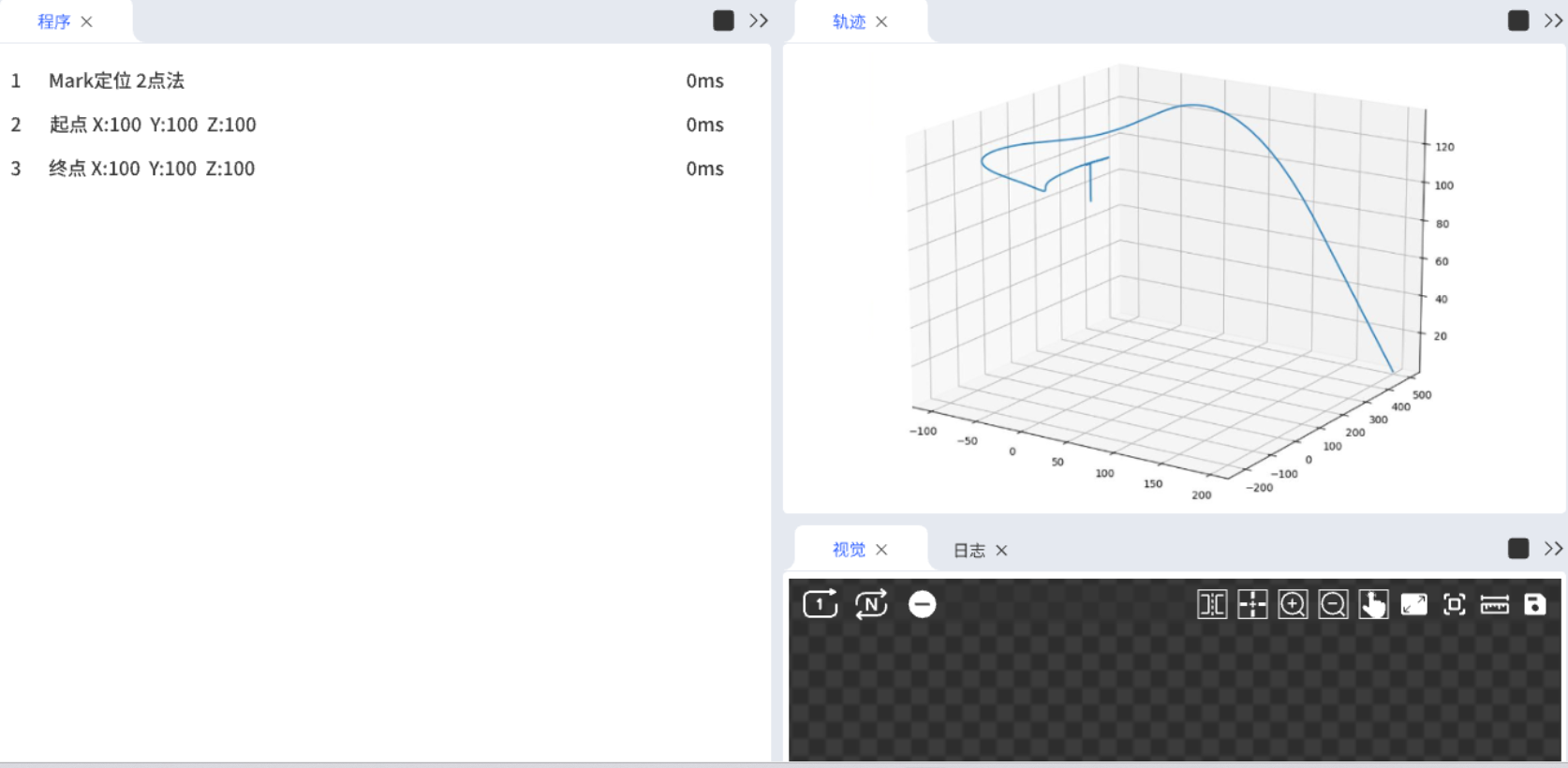

Dispensing Process Commands/Trajectory Reference

iNexBot Dispensing Advantages

Precision Control: Proprietary algorithms optimize dispensing time, volume, and pressure for stable quality.

User-Friendly: Strong system interactivity with intuitive visualization and simplified operation.

Multi-Station Support: Synchronous/asynchronous multi-valve operation with built-in胶路检测 for smoother processes.

High Accuracy: Supports diverse non-standard dispensing processes with easy recipe management.

Specialized Commands: Single-point dispensing, quadrilateral filling, etc., to meet varied customer needs.

Efficiency: 20% faster production cycle compared to market competitors.